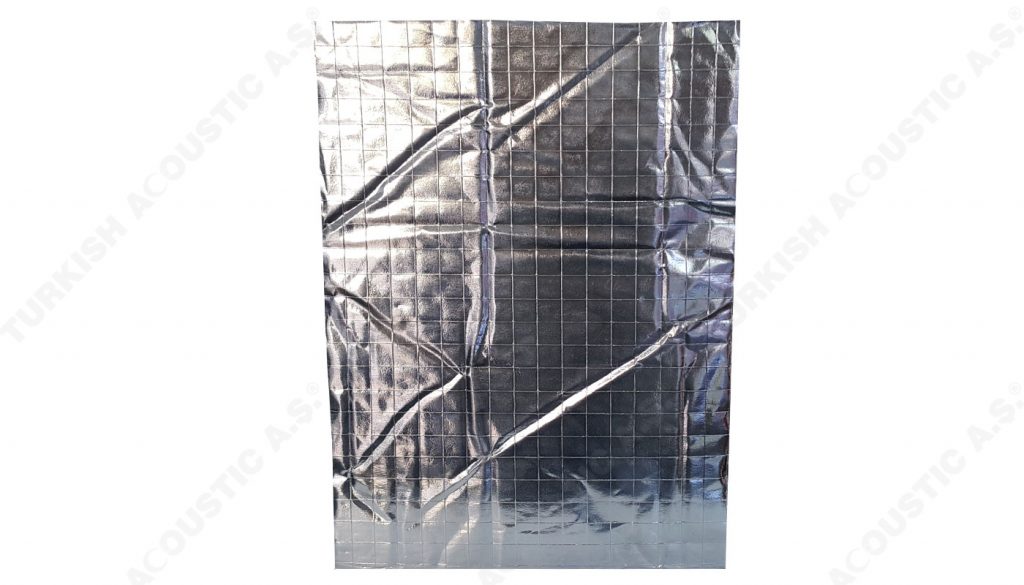

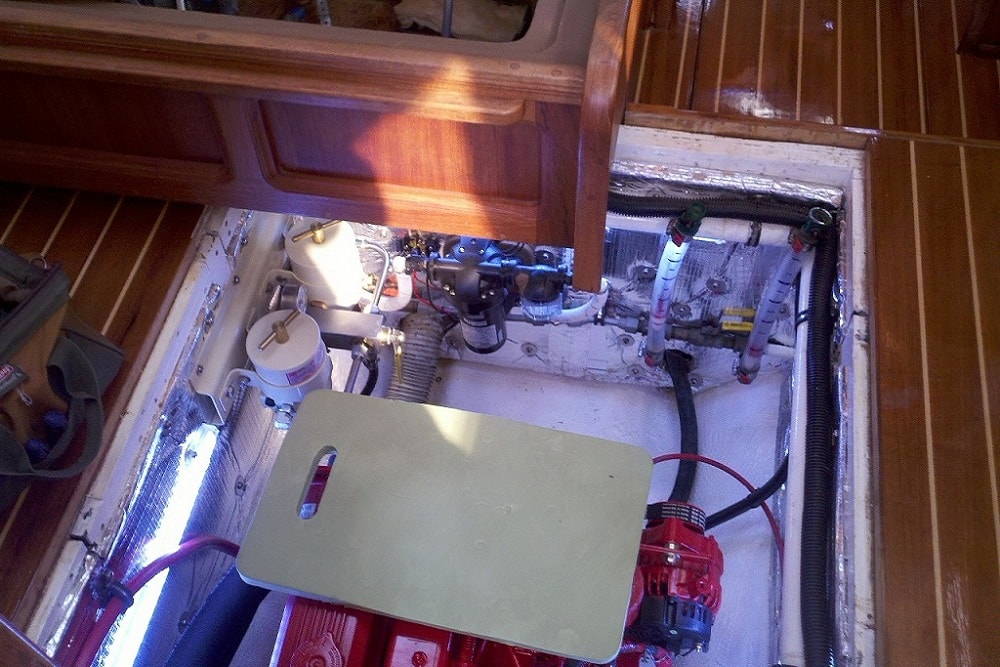

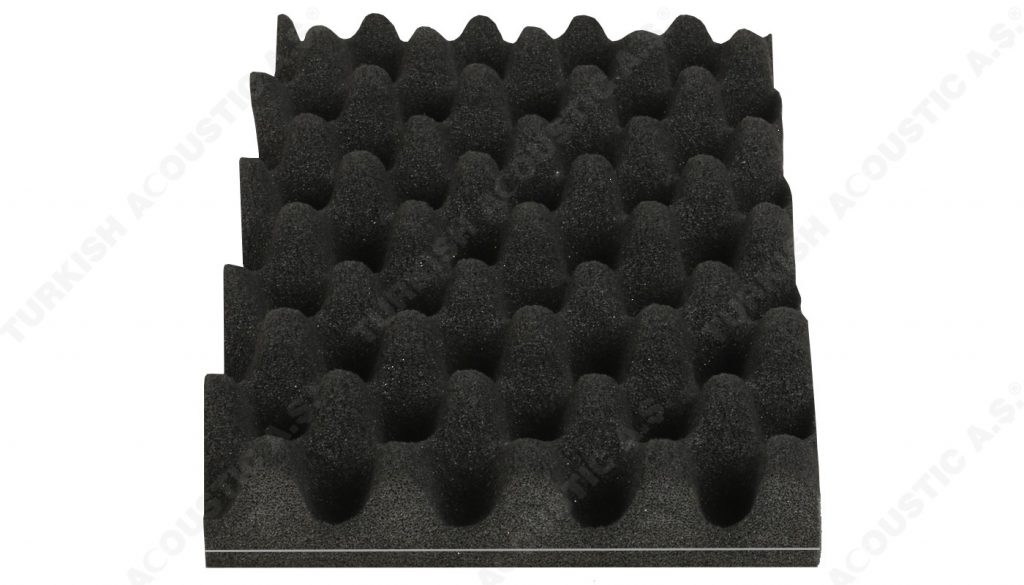

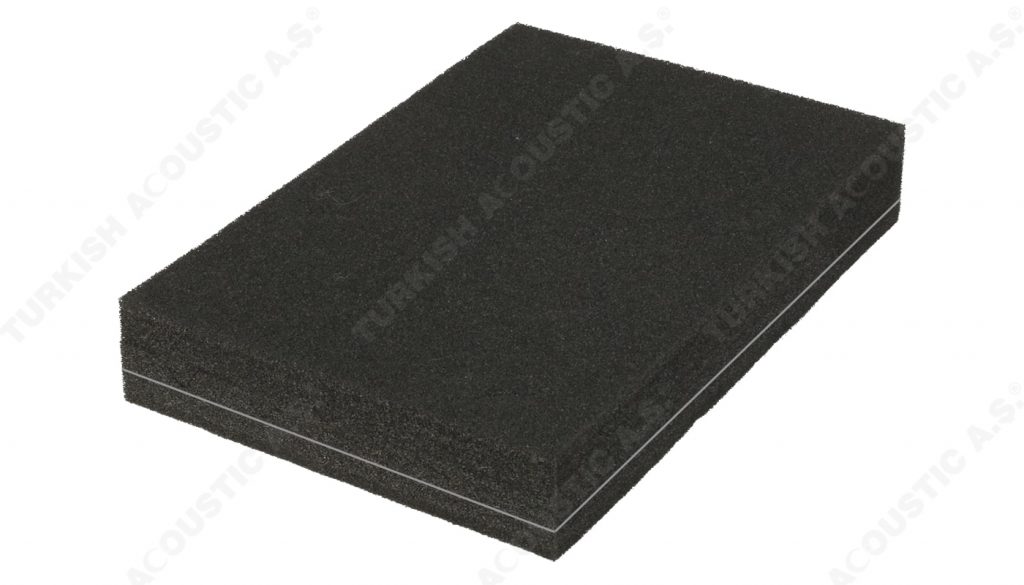

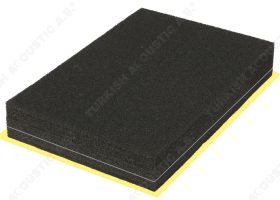

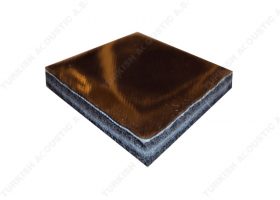

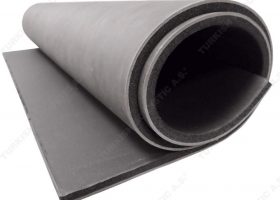

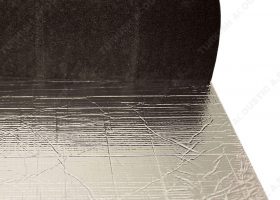

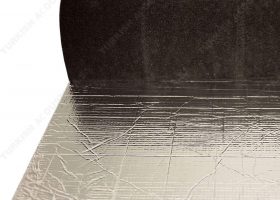

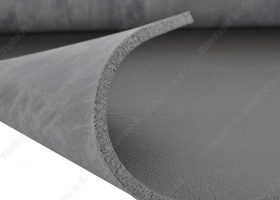

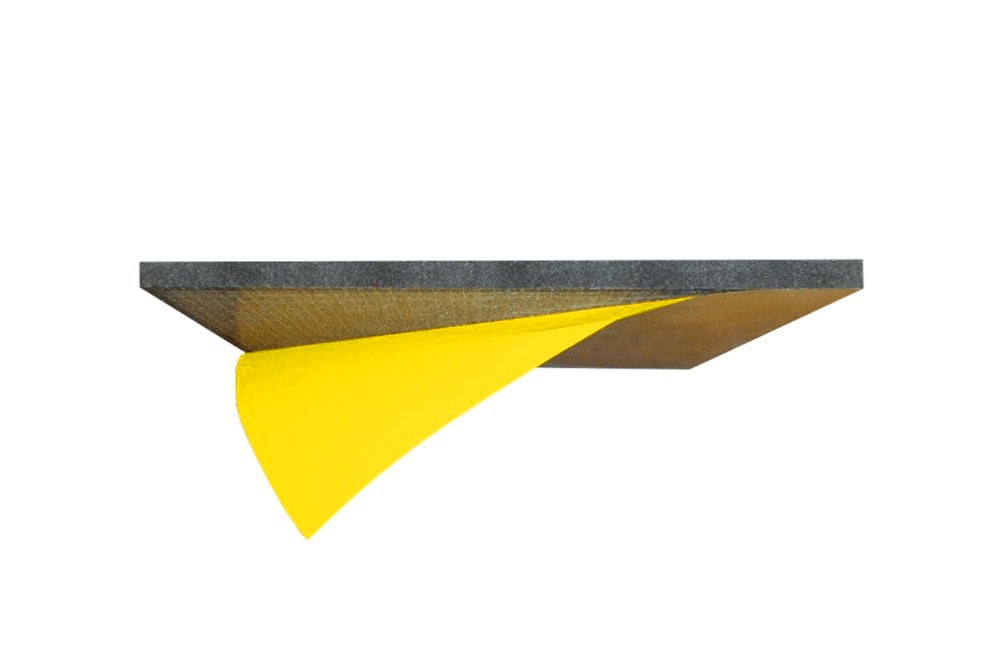

Yacht Marine Foam: It is an aluminum and polyester laminated coating resistant to external conditions. It provides the best performance with the selection of high quality raw materials. Yacht marine is produced in fireproof feature by laminating lead equivalent EPDM-based heavy barrier to strengthen sound insulation between the sound insulation panels used inside the boat engine room and the engine cabins and the material covered with aluminum foil on one side. are laminated products and are highly effective sound insulation isolation sponges. Lead-plated sponges, which offer a highly effective and precise solution, are made ready for sale by covering their outer surface with aluminum foil or PVC so that they do not absorb oil and water. Flame retardant, self-extinguishing polyurethane-based material. It has high sound absorption values thanks to its optimum porous structure. External factors such as water, oil and dust do not affect product performance. Certificates with certificates are available on our website. It complies with technical specifications. As Turkish Acoustic, we are always at your service. Please choose us.

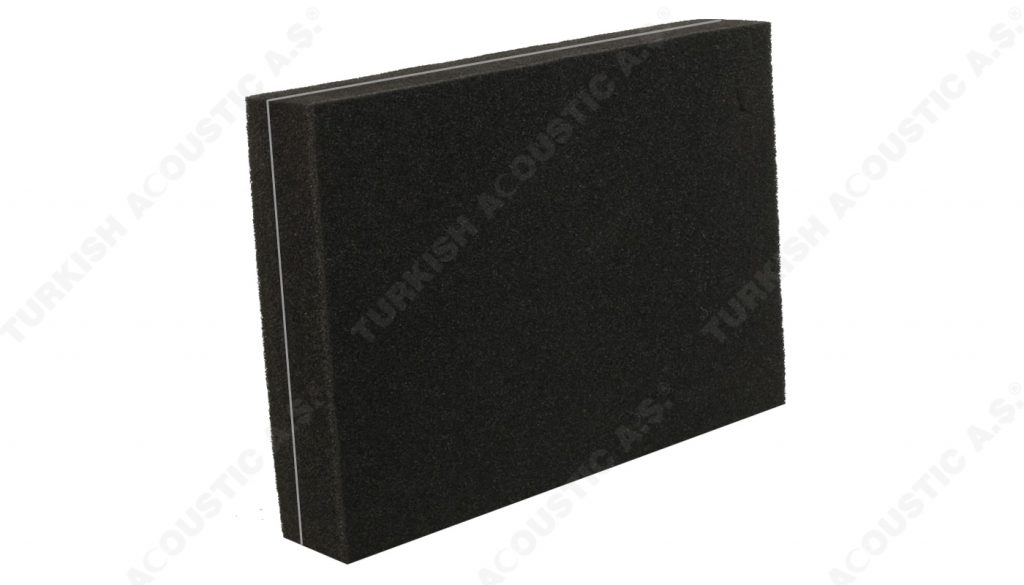

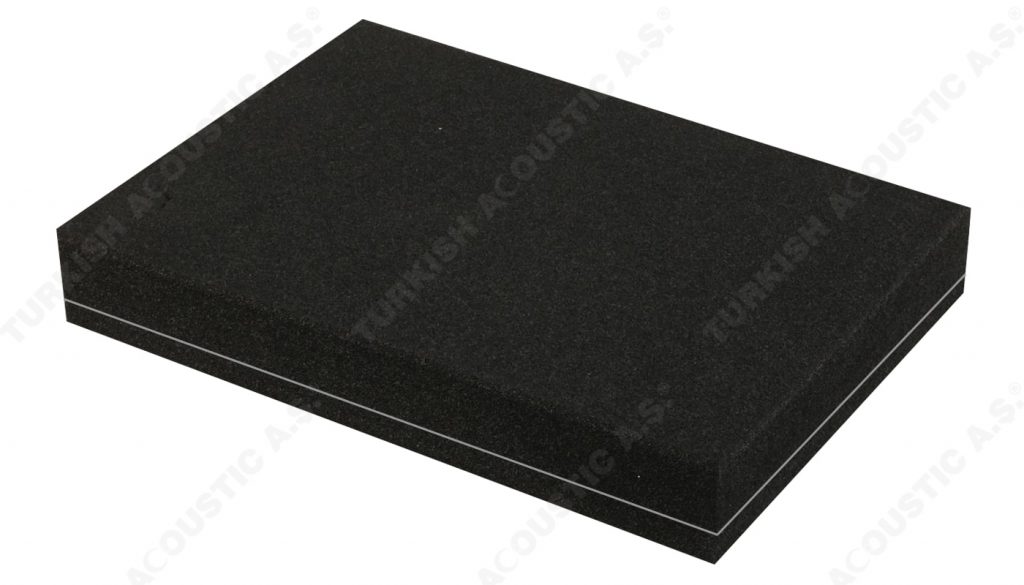

Yacht Marine Foam Dimensions: 100 cm x 100 cm or 100 cm x 200 cm Plate dimensions, 20 mm - 30 mm and 40 mm - 50 mm are offered for retail sale.

Yacht Marine Foam Package Contents: Aluminum coated fireproof sponges 50 cm x 100 cm size plate is sold in 20 packages. 1 Pack 10 m² Sold.

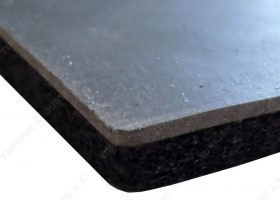

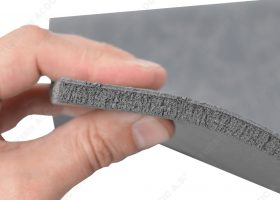

Yacht Marine Foam Product Thickness: 10 mm - 20 mm - 30 mm - 40 mm - 50 mm - 60 mm - 70 mm - 80 mm - 90 mm - 100 mm

Yacht Marine Foam Color types: Black (dark andesite gray) are sold as standard, colored production is possible.

Yacht Marine Foam Uses : Yachts and boats in the marina, nacelle, generators cabin, m Užice room, studio, radio, publishing, sports hall, entertainment venues.

Yacht Marine Foam Production: Production of special thickness 50 mm and above is possible. Custom cut to size is possible.

Yacht Marine Foam Density: 50 to 60 Kg / M³ It is possible to produce special production in desired density and thickness.

Note: 30 mm product is between 25 - 30 mm, 40 mm thickness is tolerated between 35 - 40 mm.

Our products have flameproof and nonflammability certificates and nonflammable/flameproof Firex; in nonflammability BS476: class 0 and Unı 9175:2008 M1 documents in European norms. They are anti-bacterial thanks to their dead cell structure and do not produce any mycose and bacteria.

Our products have flameproof and nonflammability certificates and nonflammable/flameproof Firex; in nonflammability BS476: class 0 and Unı 9175:2008 M1 documents in European norms. They are anti-bacterial thanks to their dead cell structure and do not produce any mycose and bacteria.

Yacht Marine Foam are in 100 cm x 100 cm plates, and there are 10 plates, that is, 10 m² of product in their packages. It is sold in retail and wholesale as 30 mm and 40 mm as standard. It can be produced in different thicknesses and sizes as a special production if you wish. Please contact our technical office for detailed information.

Yacht Marine Foam are in 100 cm x 100 cm plates, and there are 10 plates, that is, 10 m² of product in their packages. It is sold in retail and wholesale as 30 mm and 40 mm as standard. It can be produced in different thicknesses and sizes as a special production if you wish. Please contact our technical office for detailed information.