Product Description

Product Images

Application Gallery

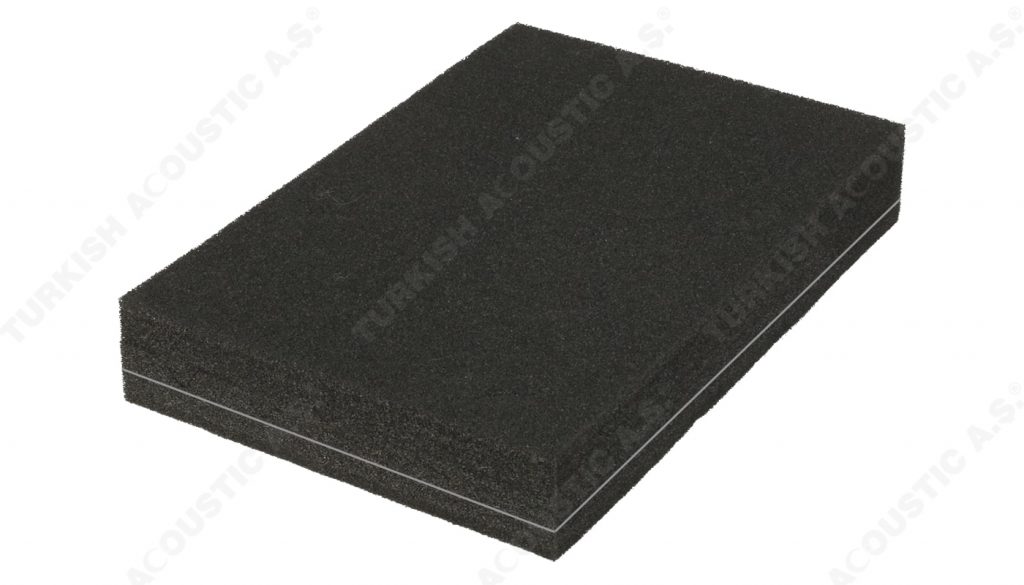

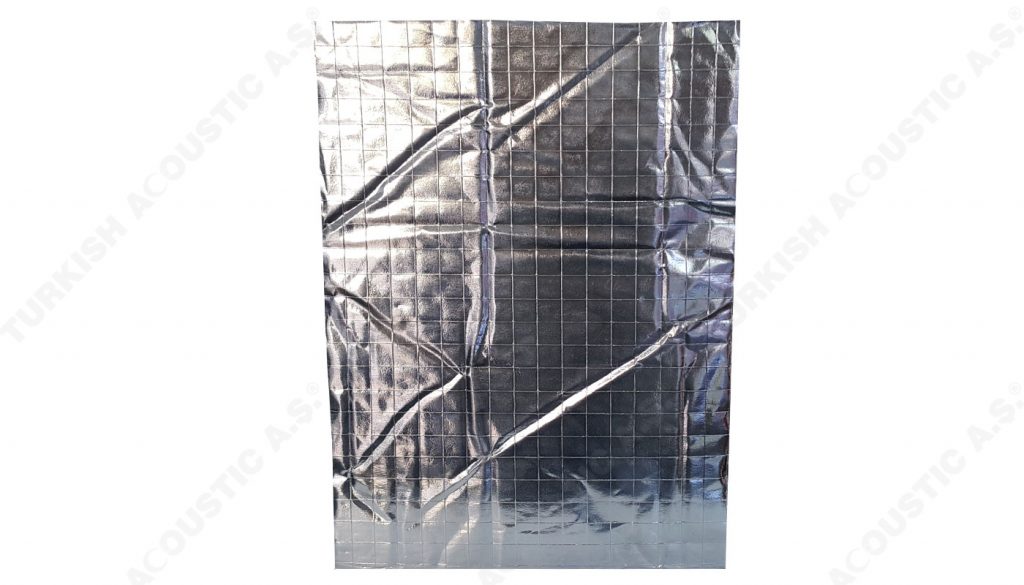

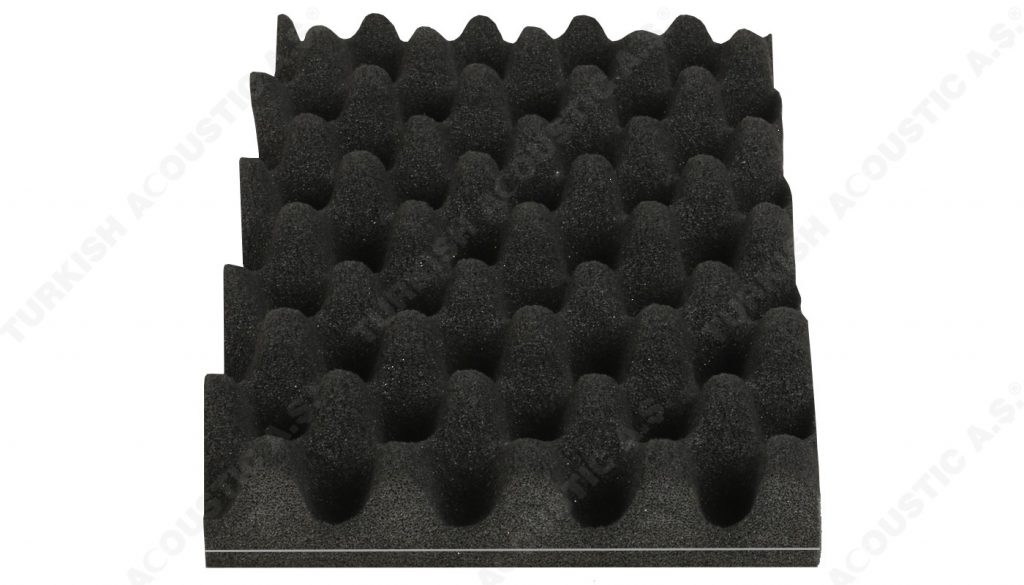

Barrier Egg Foam

Yacht Marine Foam

Felt Fireproof Foam

Product Description

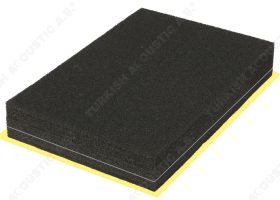

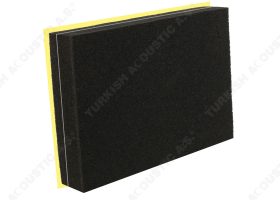

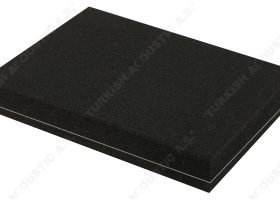

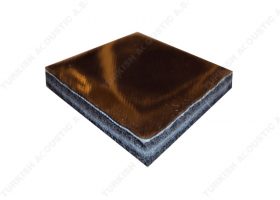

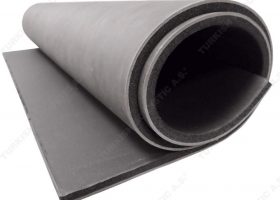

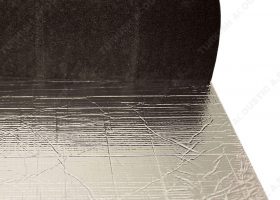

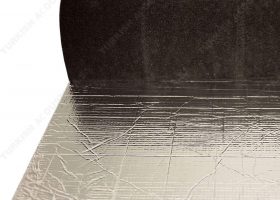

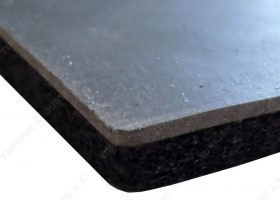

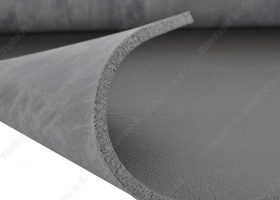

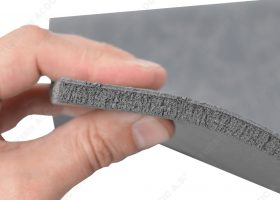

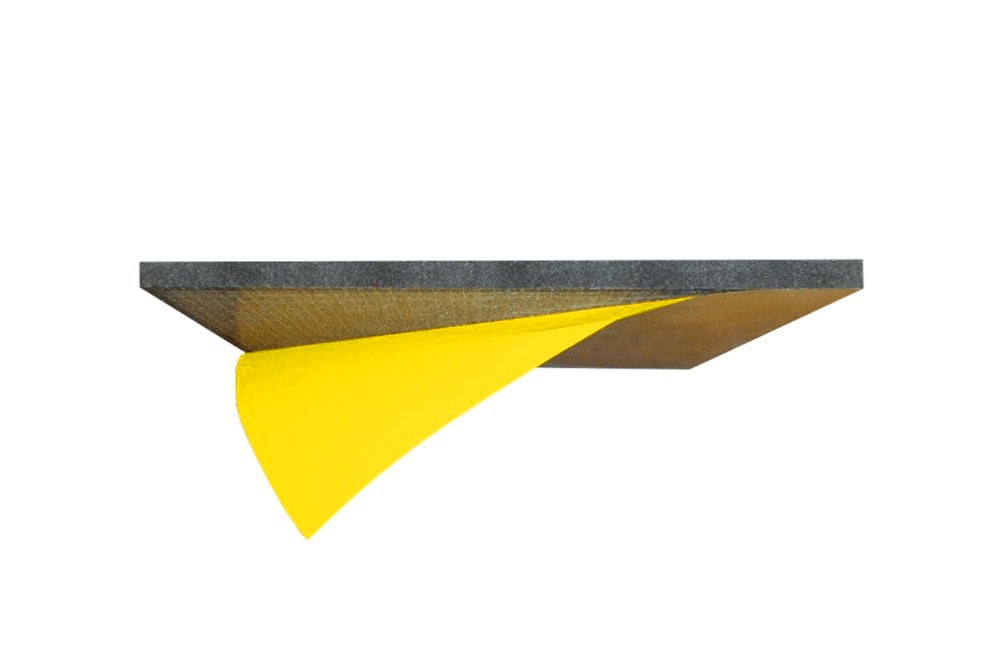

Fireproof Barrier Foam : PU coated acoustic sponges, which are produced by our company in accordance with international standards and provide acoustic sound insulation solutions in areas where non-flammability is important, are fireproof sponge foam products. Usage areas of aluminum coated acoustic fireproof sponges; in ventilation ducts, mechanical rooms, generator and compressor cabins, in short, at every point where sound insulation is required; In areas where acoustic solutions are required such as disco, restaurant, cinema, concert, meeting halls; It is used in crowded environments such as airports, government buildings, and in situations where noise and echoes (parasitic sounds) need to be controlled.

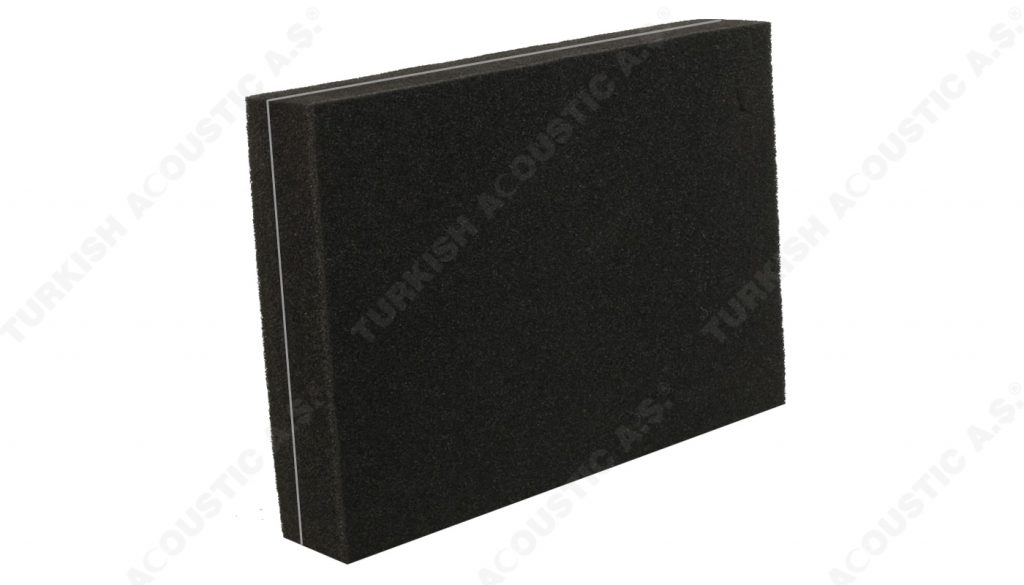

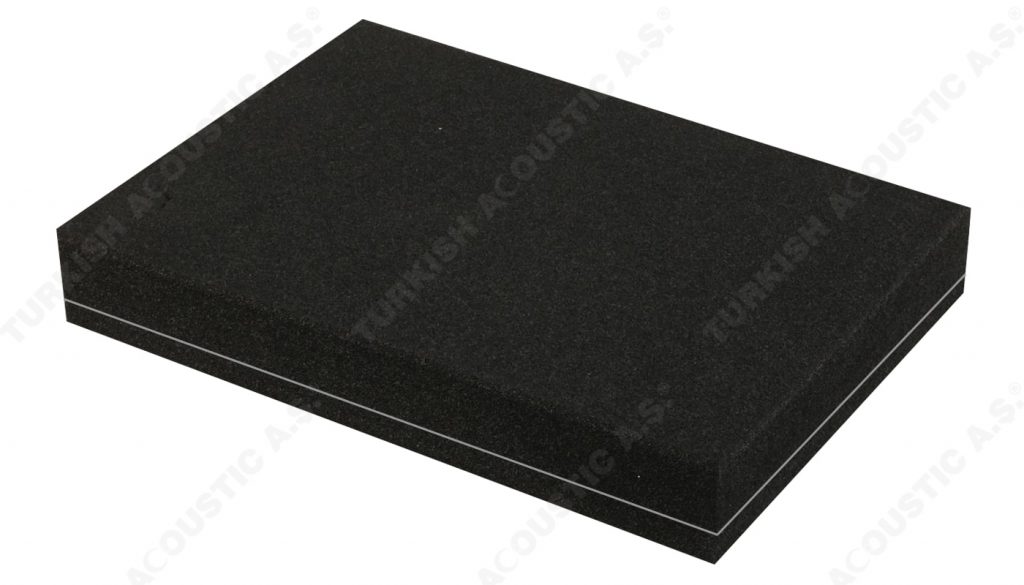

Fireproof Barrier Foam

Fireproof Barrier Foam

Fireproof Barrier Foam

Fireproof Barrier Foam

Fireproof Barrier Foam

Fireproof Barrier Foam

Product Images

Application Gallery

Barrier Egg Foam

Yacht Marine Foam

Felt Fireproof Foam

Our products have flameproof and nonflammability certificates and nonflammable/flameproof Firex; in nonflammability BS476: class 0 and Unı 9175:2008 M1 documents in European norms. They are anti-bacterial thanks to their dead cell structure and do not produce any mycose and bacteria.

Our products have flameproof and nonflammability certificates and nonflammable/flameproof Firex; in nonflammability BS476: class 0 and Unı 9175:2008 M1 documents in European norms. They are anti-bacterial thanks to their dead cell structure and do not produce any mycose and bacteria.

Fireproof barrier sponges are in 100 cm x 100 cm plates, and their packages contain 10 plates, ie 10 m² of products. It is sold retail and wholesale as 30 mm and 40 mm as standard, it can be produced in different thicknesses and sizes as special production if you wish. Please contact our technical office for detailed information.

Fireproof barrier sponges are in 100 cm x 100 cm plates, and their packages contain 10 plates, ie 10 m² of products. It is sold retail and wholesale as 30 mm and 40 mm as standard, it can be produced in different thicknesses and sizes as special production if you wish. Please contact our technical office for detailed information.