Product Description

Product Images

Application Gallery

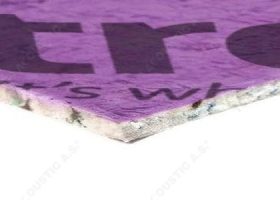

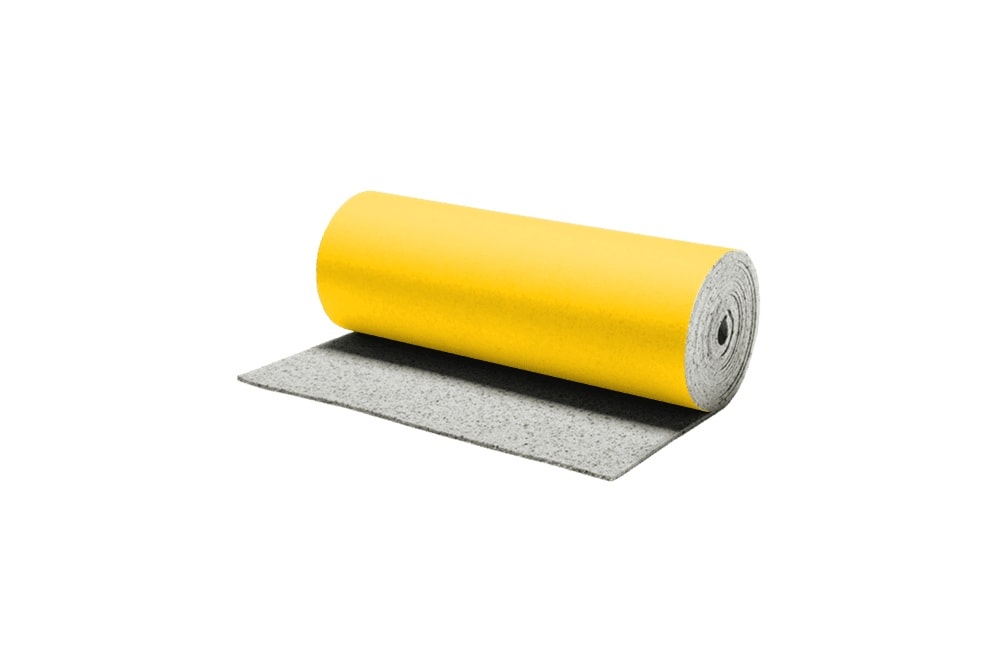

Roll Bondex Sponge

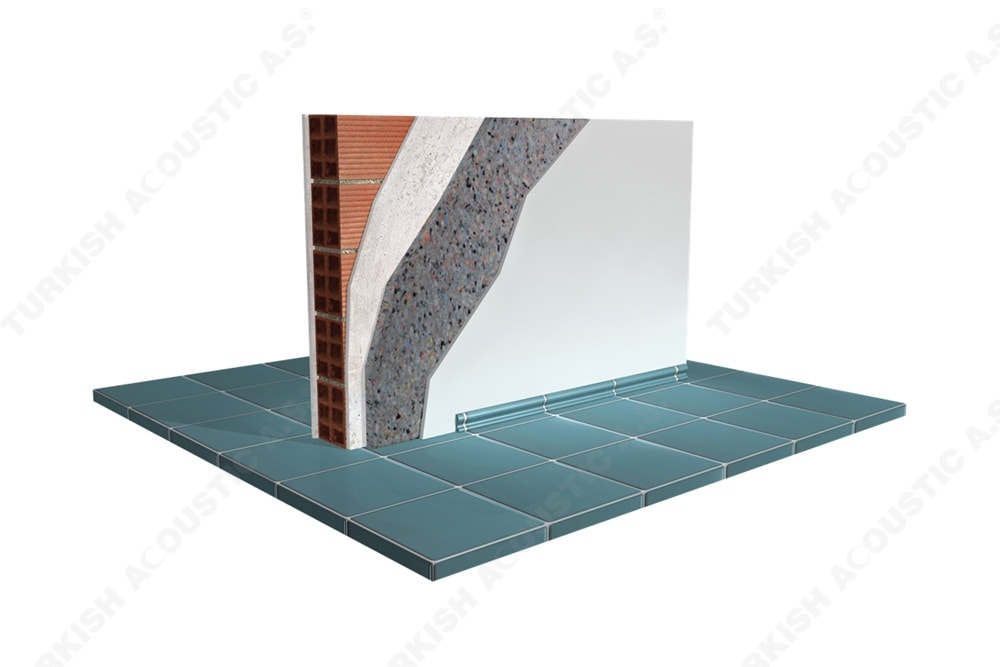

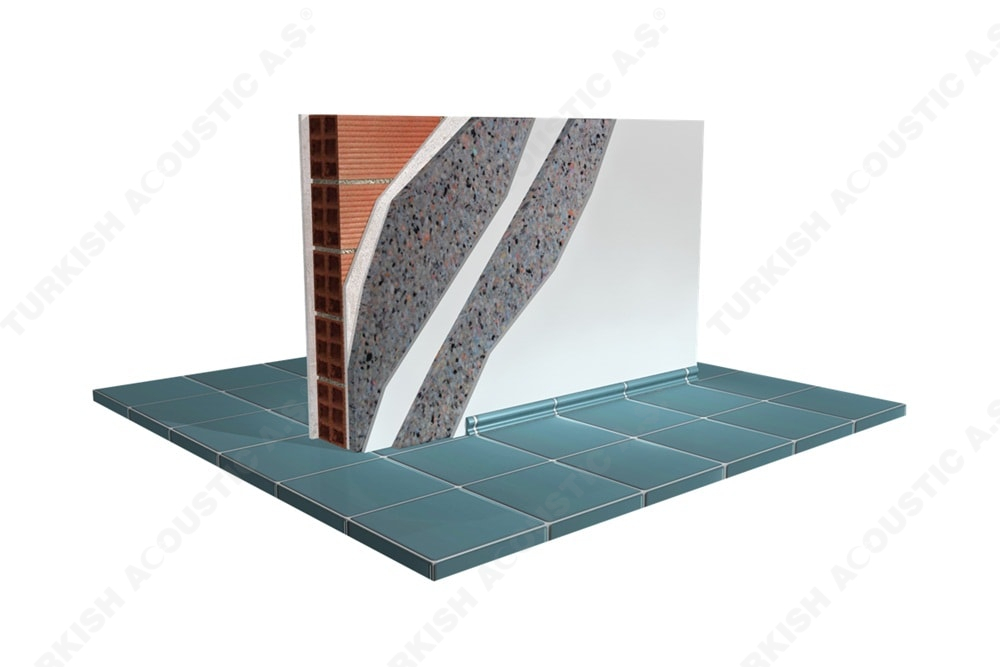

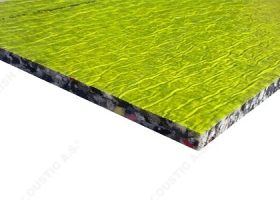

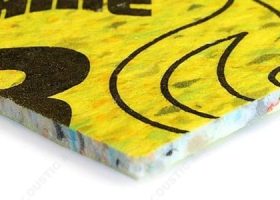

Barrier Bondex Sponge

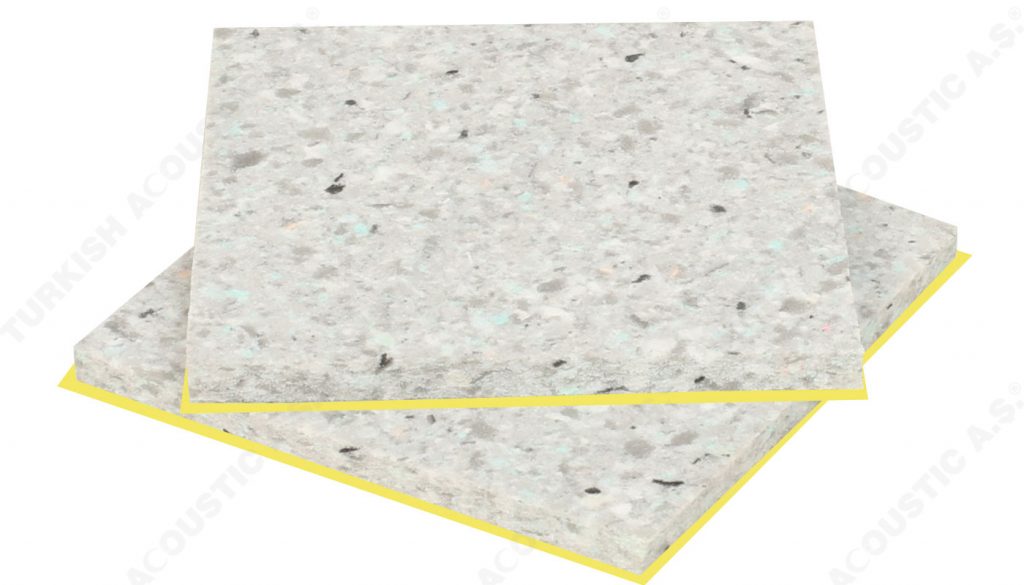

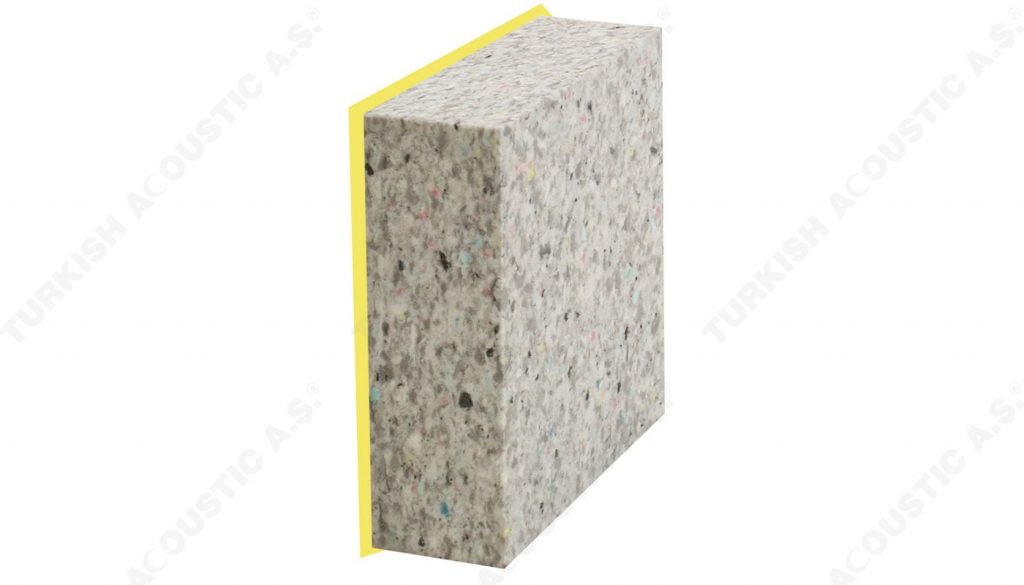

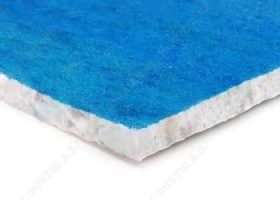

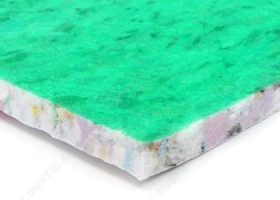

Acoustic Bondex Sponge

Product Description

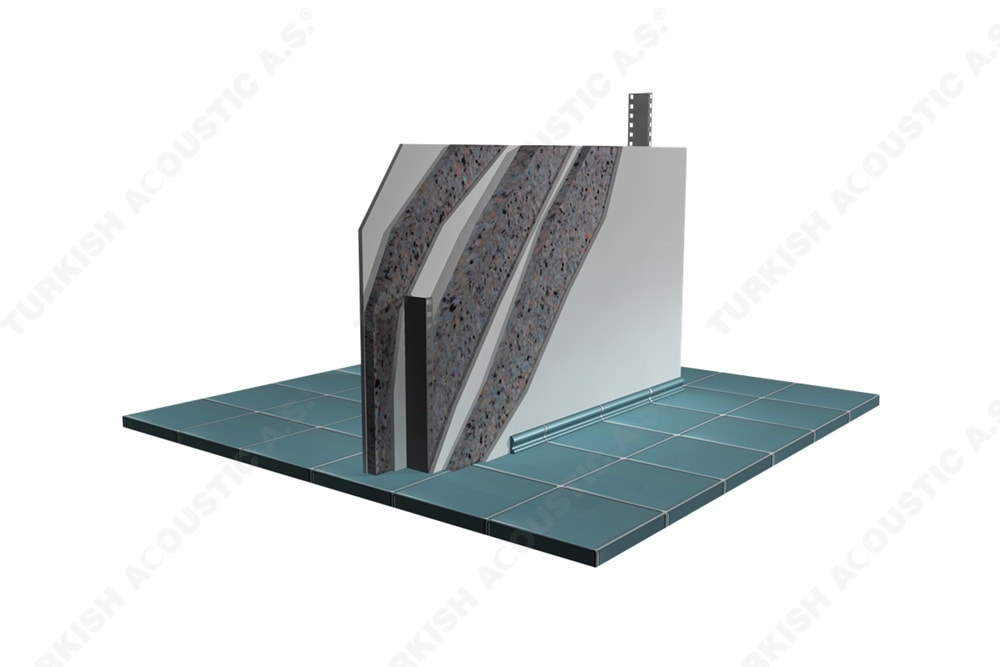

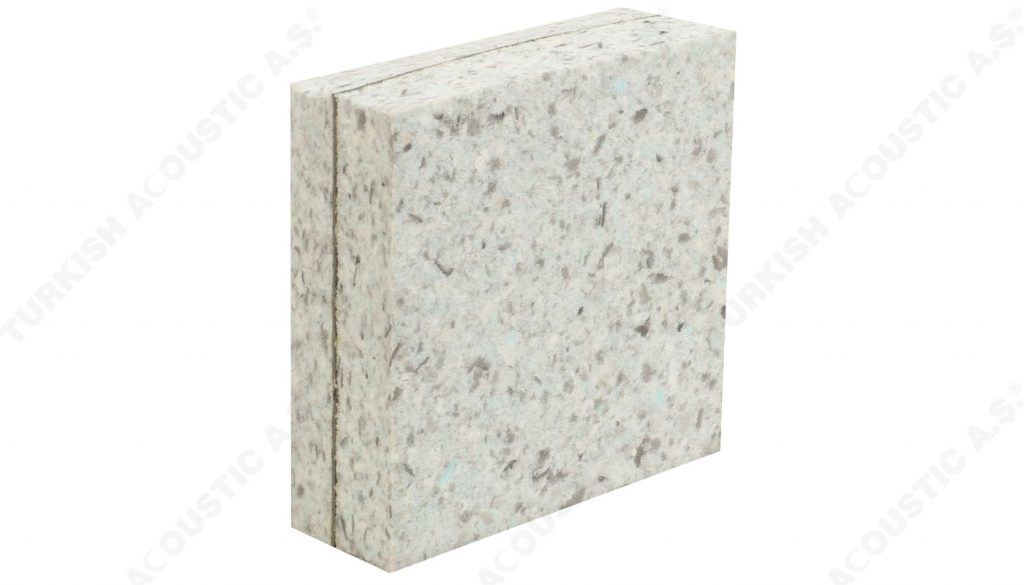

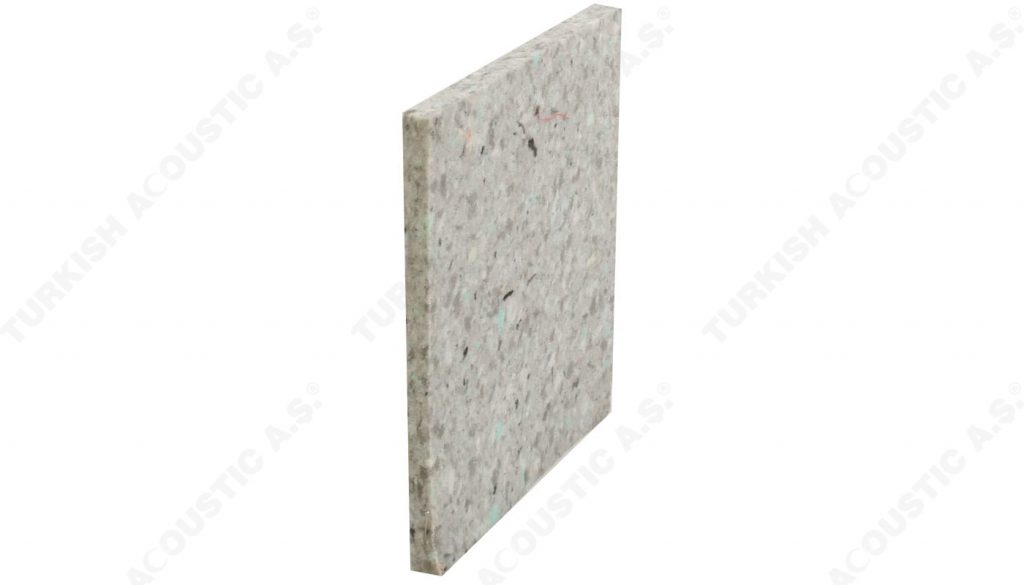

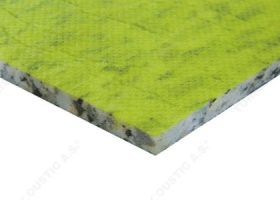

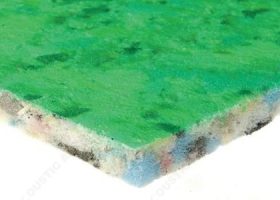

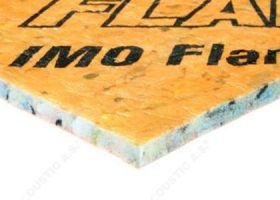

Adhesive Bondex Faom : Bondex sponges are among the most preferred products in the market thanks to their superior soundproof structure. Bondex sponges, which are produced as self-adhesive, allow you to apply easily and provide professional level absorption in sound transitions. Thanks to its flame retardant structure, you can use it in industrial areas without creating any danger. It is used as a bumper and wedge material in the automotive industry and as a wrestling mat in the sports equipment industry at various points. If desired, heavy EPDM sound barrier can be laminated between two bondex and can be produced as a barrier bondex.

Adhesive Bondex Foam

Adhesive Bondex Foam

Adhesive Bondex Foam

Adhesive Bondex Foam

Adhesive Bondex Foam

Adhesive Bondex Foam

Product Images

Application Gallery

Roll Bondex Sponge

Barrier Bondex Sponge

Acoustic Bondex Sponge

Certification

Technical Documents

Our products have flameproof and nonflammability certificates and nonflammable/flameproof Firex; in nonflammability BS476: class 0 and Unı 9175:2008 M1 documents in European norms. They are anti-bacterial thanks to their dead cell structure and do not produce any mycose and bacteria.

Our products have flameproof and nonflammability certificates and nonflammable/flameproof Firex; in nonflammability BS476: class 0 and Unı 9175:2008 M1 documents in European norms. They are anti-bacterial thanks to their dead cell structure and do not produce any mycose and bacteria.

Bondex acoustic sponges are in the form of 100 cm x 100 cm plates, and their packages contain 10 plates, 10 m² of products. It is sold by retail and wholesale as 30 mm and 40 mm as standard, it can be produced in different thicknesses and sizes as special production if you wish. Please contact our technical office for detailed information.

Bondex acoustic sponges are in the form of 100 cm x 100 cm plates, and their packages contain 10 plates, 10 m² of products. It is sold by retail and wholesale as 30 mm and 40 mm as standard, it can be produced in different thicknesses and sizes as special production if you wish. Please contact our technical office for detailed information.